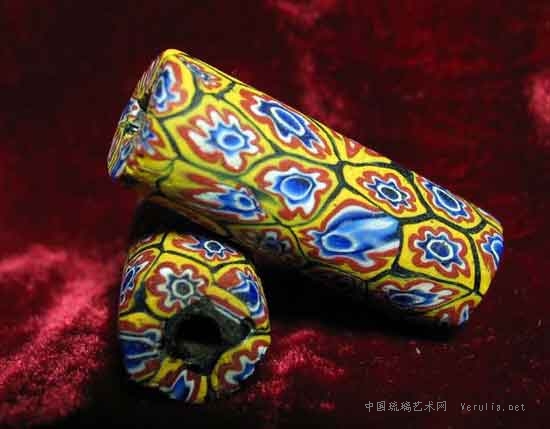

这种工艺叫 millefiori ,意大利语"一千朵花",

工艺原理就是比较复杂的马赛克(MOSAIC),

最早也出现在西亚,前罗马时代工艺被流传整个地中海沿岸,

后来成为著名的贸易珠品种。

找了些millefiori工艺的资料,我翻译的水平不好,就这么看吧:)

History of millefiori

Millefiori-decorated objects have been created intermittently from the time of ancient Mesopotamia to the present day. Bowls of fused millefiori canes are known to have been made in ancient Rome and Alexandria, and there are a few references to examples of millefiori work during the Renaissance. By the eighteenth century, however, the technical knowledge for the manufacture of millefiori was lost. It was not until the nineteenth century that a revival of the technique appeared. By the end of the 1830s, millefiori were manufactured successfully in Silesia-Bohemia. Within two or three years of its rediscovery, factories in Venice, England, and France were also producing quantities of millefiori canes.

Process of manufacture

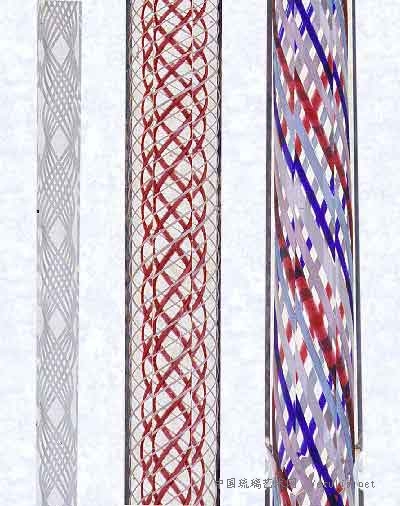

Cut from long, thin glass rods, millefiori canes were prepared in the following manner: The glassworker took a gather of molten glass on a pontil, or long iron rod, and rolled it back and forth on a marver, or flat surface, until it formed a solid cylinder. The cylinder was then pressed into a die-cut mold that had a geometric shape or the outline of a specific animal or figure. The piece was further embellished by dipping on additional layers of varying colors of glass. As each layer was added, it was rolled onto the ever-growing cylinder or pressed into increasingly larger molds to vary the cane's ultimate design.

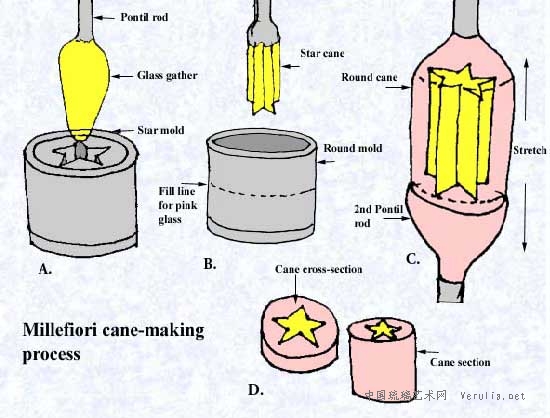

这张图的步骤分解:

This graphic illustrates steps in the proces of creating a patterned glass cane.

Step A: A gather of molten glass is lowered into a steel pattern mold, which may be several inches in diameter.

Step B: The now (star)shaped gather is then lowered into another mold (this one round)that is half-filled with molten glass of a second color. The gather picks up the colored glass, (encasing the star).

Step C: A second pontil with another gather of glass is attached to the opposite end of the patterned gather. The gather is then stretched out many feet in opposite directions to form a thin cane, perhaps only 1/4 to 1/2 inch in diameter.

Step D: The thin cane is sliced into smaller sections to use in millefiori paperweights.

The finished cylinder of glass, approximately six inches long and three inches in diameter, was reheated until pliant. Pontil rods attached to each end were pulled apart, stretching the yielding cylinder pencil-thin. The stretched cooled cane was then sliced into hundreds of little discs, each an exact miniaturization of the original design. For more complex designs, lengths of the stretched canes were cut into six-inch pieces, bundled in a geometric pattern, heated until fused together, stretched pencil-thin, and slices again. In this manner, glassworkers were able to produce unlimited millefiori cane designs from a limited selection of molds.

[1] [2] 下一页

|